services Detail

services Detail

Services

Contract Manufacturing

Motherson is a world leader in lean manufacturing. We accelerate your product development through expertise in design for manufacture, project management, supply chain management and support throughout your product life-cycle.

Our customers have a single point of contact for the end-to-end manufacture of high quality moulded enclosures, complex electronics and specialised coatings, including assembly and logistics.

This full service is competitively priced, with the security of quality-driven processes and peace of mind knowing your intellectual property is in safe hands.

Overview.

Motherson partners with customers for the effective end-to-end manufacturing of new and existing products.

Your single point of contact will oversee component procurement, manufacturing, quality control and product distribution.

Our experienced, cross-functional team of engineers are well equipped to translate your product opportunity from prototype to full manufacture, in high or low volumes.

With more than 30 years experience in global logistics and distribution, you’re partnering with a manufacturer that supports customer growth into complex and competitive markets.

Capabilities.

- Engineering design using the latest Catia 3D Cad, SPEOS simulation and Altium PCB software

- We specialise in the production of functional and decorative thin film coatings, customised plastic moulded enclosures, automated electronics manufacturing and product assembly

- Our moulding machines range in size from 10 to 500 tonnes, all with robotic capability

- Our electronics facility is housed in an environmentally controlled clean room, with 3D inspection capability on high speed, high volume lines

- We offer a broad scope of validation testing for lighting, structures, electronic and mechatronic applications

- Our versatile approach to assembly and logistics management processes are adaptable to individual project needs

Our process.

- Our in-house design team will assess your design for manufacture to ensure cost effective production

- We adhere to the highest quality

and environmental standards,

accredited world-wide:

ISO 9001

ISO 14001

ISO 13485

ISO 17025

IATF 16949 - Assembly lines at Motherson can be manual, semi-automated or fullyautomated and are housed in our impressive 16,000m2 facility

- Your final product is distributed to your destination with tailored logistics solutions including packaging, export and delivery

Our people.

Our world-class engineering, project management and logistics teams will guide you through each stage of manufacture with clear and frequent communication.

Contact us for more information.

Services

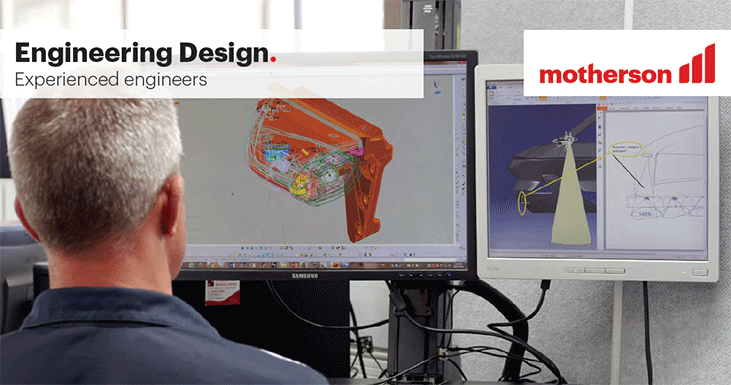

Engineering Design

Our highly skilled in-house design and engineering team are committed to guiding your product development. We take a cross-functional team approach to learn about your specific requirements and assist in your next steps.

Thanks to the continuous support of our customers, Motherson has become a trusted partner not only for the design, development and engineering phases, but also the manufacture and validation of your end product. We’re quality accredited to ISO9001, medical ISO13485 and automotive IATF16949.

Design and development.

We have a world-class engineering facility, which is based on applied engineering discipline, technical excellence and a cross-functional development team approach.

We take innovative product concepts from Technology Readiness Level 2 or 3 through to clinical trials, device certification and manufacture.

Our experience extends from automotive to medical devices, IoT devices, renewables and more.

We have a dedicated team that evaluates concepts and provides guidance through the entire process.

Our process.

- Concept product design

- Concept prototype ↔ concept validation

- Production product design

- Production product validation

- Production product certification

- Production scale up

We are able to provide ongoing early stage manufacture and assist with expansion beyond the region as well as globalisation.

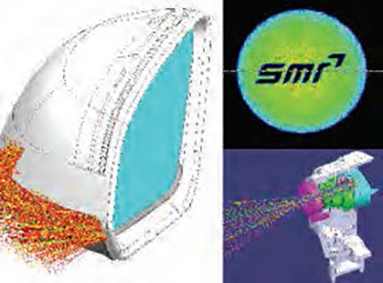

Computer-aided product design.

- Catia V5: 25+ seats covering surfacing, surface analysis, solid modelling, kinematics, CAE and Smart Team PDM

- Autodesk Inventor

- SDRC Ideas

- Altium PCB design software

CAE/finite element analysis MSC and Hyperworks software suites incorporating:

- Static analysis

- Dynamic analysis

- Linear and non-linear computation

- Structure optimisation

- Kinematic analysis

- Modal analysis

- MOLDFLOW® and MoldEx

- SPEOS optical and lighting analysis

- LucidShape optical design and analysis

- Zemax optical design and analysis

- Thermal/CFD simulation

Project management.

All aspects of the product development life cycle are managed in-house, ensuring complete control of all processes.

From concept to reality, our vertically integrated structure ensures efficient management of each project from agreed quote to quality product, on time and within budget.

Contact us for more information.

Services

Coating

We delight customers with the proven performance and durability of our advanced surface coatings including flexibility in colour, brightness and transparency.

Motherson coatings are designed using multiple metals, silicon and their oxides and nitrides. We support the high standards of our customers with optical-class, contaminant free moulding processes and precise quality control, monitoring real time process parameters. Motherson advanced surfaces are built to last in harsh conditions for decorative and functional applications at tolerences <15nm.

Overview.

We specialise in using various thin film coating techniques including magnetron sputtering, thermal evaporation and various forms of customised plasma-enhanced chemical vapour deposition.

The wide scope and capability of our coating processes allow substrates of various sizes and geometries to be 3D-coated with precision and speed at a low cost.

We have the ability to create engineered surfaces using custom-design coatings and interfaces for decorative and functional applications.

Capabilities.

- Liquid silicon hardcoats for abrasion resistant, environmentally durable and transparent coatings on plastic substrates that can be deposited using dip or spray methodologies

- Thermal evaporative metallisation of aluminium on plastic substrates

- High-rate, high-throughput sputtering for single or multi-layer deposition of metal or metalloid coatings that include chrome, aluminium, titanium, indium, silicon, germanium and numerous alloys

- Reactive sputtering of metal oxide/ nitride and silicon oxide/nitride coatings

- Organic coatings deposited using PE-CVD (Plasma-Enhanced Chemical Vapour Deposition) using multiple systems across a range of frequencies

- Thickness range from 5 to 100’s of nanometres with tight tolerances on complex geometries, depending on application, approaching ±2nm.

Quality.

To ensure optimum quality, surface finish and performance, all key processes – from moulding to vacuum metallising – are performed under environmentally controlled conditions in clean rooms.

Advantages.

Strong fundamental coating design, research and development capabilities, strengthened with a long-term collaborative partnership with the University of South Australia’s Thin Film Coatings group at the Future Industries Institute.

Contact us for more information.

Services

Moulding

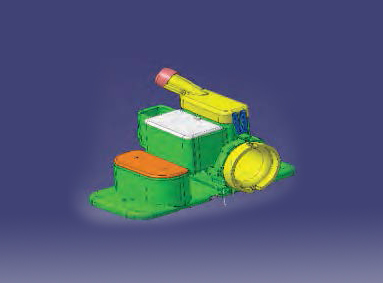

Using state-of-the-art precision moulding techniques, we empower our customers to explore complex plastic-moulded components.

From the flexibility of two component (2K) moulding, to the precision of optical moulding, and the warp-free, lightweight properties of mucell moulding, Motherson works with you to make the right choice for your product.

The latest technology, moulding machines ranging in size from 10 to 500 tonnes, combined with our years of experience, means we can guide you from product development to delivery.

Overview.

We specialise in multiple technologies for injection moulding.

Our 70 advanced moulding machines, ranging in size from 10 to 500 tonnes, produce technically and economically superior polymer products and optimised subcomponents for all products.

Capabilities.

Our process capabilities include:

- Mucell – microcellular foam injection

- Rapid temperature cycling (RTC)

- Injection compression moulding

- Precision moulding including electric machines

- Microfluidics moulding

- Optical moulding

- Gas-assisted moulding

- High temperature heating systems

- Insert moulding

- Two component (2K) moulding

- Clean room ISO class 6

Part and tool design capabilities.

Our capabilities include:

- MOLDFLOW® and MoldEx

- FEA (Finite Element Analysis)

- Multiple CAD formats supported

- Rapid tool change methodology to maximise capital capacity

Tool sourcing and maintenance.

Our toolmaking team is responsible for implementing tooling performance improvements, performing preventative maintenance and improving process capability.

We have:

- Access to multiple reliable suppliers in Germany, Japan, China & Taiwan

- An on-site tool maintenance room

Materials.

Our materials and process systems include:

- Thermoplastic and elastomer moulding using a wide range of engineering resin types, such as ABS, PP, PA6/66, POM, PBT, TPE, PC, PEI, PMMA and ASA (more than 130 different grades)

- Colour moulding

- A central desiccant drying system

- Material drying moisture measurement equipment

Our people.

Operating three shifts over 24 hours allows our experienced moulding team to provide you with complete moulding solutions.

Contact us for more information.

Services

Assembly

Our flexible approach to assembly helps us create efficient solutions for our customers. Through the use of low volume hand assembly to fully automated assistive robot assembly for high volumes, Motherson remains globally competitive with the advantage of a single point of contact for all your design and manufacturing needs.

Our customers benefit from high-precision components being assembled using lean manufacturing principles, all underpinned by robust and reliable quality-driven processes to ensure continuous improvement and customer satisfaction with every product.

Overview.

At Motherson, we choose the assembly solutions based on the needs of our customers. From low volume, hand assembly to assistive robots, or co-bots, for mid-volume projects, right up to fully automated high volume projects.

All of our assembly system solutions are designed with customers’ quality expectations at the forefront, with fully integrated testing systems installed.

The vast majority of these assembly systems are fully designed in-house.

Capabilities.

Our assembly capabilities include:

- Assembly of child parts

- Sub-assemblies

- Hardware

- Electronic circuits

- Electromechanical modules

- And more

Validation expertise.

Reliability and precision in assembly is essential for achieving the high standards required and the efficiency we expect from all of our factories.

Your advantage.

Our flexible approach to assembly systems allows us to remain globally competitive even in comparison with low-cost manufacturing countries.

Our people.

The Motherson assembly team is a world leader in lean manufacturing principles.

The company’s highly skilled assembly department – underpinned by robust and reliable processes – uses these principles to ensure continuous improvements such as reducing waste and cost, controlling inventory and maintaining quality.

Contact us for more information.

Services

Electronics

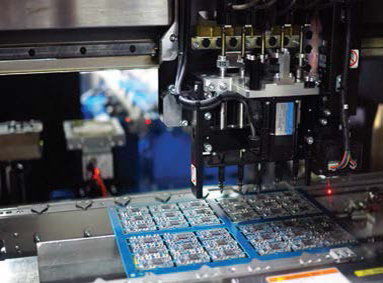

For each new generation of products, we consider cost efficiencies. Our strong capability in fully traceable, automated end-to-end electronics manufacturing means you can rely on the quality of our service, security and scaling.

Motherson helps customers achieve their goals using design for manufacture principles and sophisticated technology including PCB X-Ray, 3D solder paste inspection and 3D automated optical inspection. We’re dedicated to your success through design and development, prototype creation and full volume manufacturing in our clean room electronics facility.

Overview.

Our electronics facility is housed in an environmentally controlled clean room that is furnished with sophisticated technology for manufacturing printed circuit board assemblies (PCBA), for supply to customers around the world.

We offer:

- In-house design capability for a diverse range of solutions

- Electronic engineering design expertise covering analogue and digital

- Use of Altium PCB design software

- Development of different levels of pre-manufacture prototypes

- Global economies of scale for component purchasing

- Full volume scale-up capability

Capabilities.

- Surface mount technology lines

- Two dedicated SMT lines cater for lead and lead-free PCB products

- Yamaha YSM20: High efficiency modular pick and place machine

- Yamaha YS12: Compact high-speed modular pick and place machine

- Yamaha YSiV: High-end hybrid 3D optical inspection system (AOI)

- Pillarhouse Orissa Synchrodex: Flexible, in-line, modular selective soldering system

- Kohyoung KY 8030-3. 3D solder paste inspection machine

- Hand processing: Various through-hole or non-standard parts/components including wires, headers and connectors

- GKG GS: Fully automatic vision screen paste printer

- Pick and place reel component sizes down to 0402 and 0201

- Dage Explorer One. X-ray system with 3D inspection capability, up to 2um focal length

Laser marking

- Eunil ELM 500A: Fully automated laser printer

Conformal coating

- Selective conformal coating and UVcuring system

Terminal insertion

- Tyco P100. Stand-alone fullyautomatic pin insertion system.

Auto segregation/de-panel

- Martin router offline depanelling machine

- FKN Systek K4000. V-Groove depanelling machine

- FKN Systek N100. Nibbler depanelling machine

Testing

- PET tester

- Ability to design and manufacture dedicated electrical functional testers

- In-process testing. Customised functional testing, automated optical inspection, draw test and illumination.

Contact us for more information.

Services

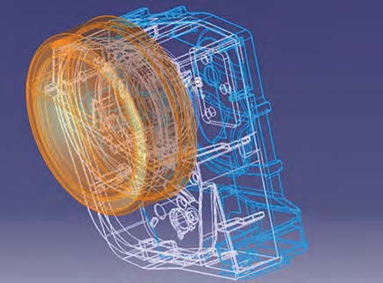

Optic Lighting

Our customers’ creativity has changed the way we think about lighting solutions. We’ve applied our strong automotive capabilities to create unique and visually appealing optic solutions to medical devices and a new wave of ambient lighting for car interiors.

Motherson uses leading edge technology to design and manufacture complex optic effects, leaving our customers secure in the knowledge that their product will be tested and validated during the design process, before being manufactured from high quality optical grade plastic components.

Overview.

We provide complete optics solutions, particularly involving complex design where LED light is ‘piped’ to create unique and visually stimulating effects.

Optics capabilities.

Our optics design and development expertise include:

- Optic modules incorporating incandescent bulbs, LEDs and other light sources

- Geometry optimisation using SPEOS simulation software integrated into a Catia 3D CAD package to accurately predict optic module output before manufacture

- Optic module integration into existing products

- Physics-based photo-realistic product visualisation in both lit and unlit conditions

- Optics output simulation and product visualisation

- LED selection and performance optimisation

- LED driving circuit development, including PCB integration into optic modules

- Prototype manufacture for final product approval before design release

Validation expertise.

Our validation expertise includes:

- Complete in-house photometric test facilities

- Mechanical and electrical test facilities

Manufacturing expertise.

Our manufacturing expertise includes:

- High quality injection moulding of optical-grade plastic components

- In-house electronics SMT “pick and place” manufacturing facility

- Multiple lamp module manufacturing technologies including plastic welding (vibration, hot-plate and ultrasonic) and automatic testing in accordance with IATF/TS16949

- Vacuum metallisation coating of aluminium and chrome

- PC lens hardcoating for scratch and UV resistance

- Flexible assembly cells for lower to mid volumes

- Semi and fully automated cells for higher volumes

- 100 % online testing of key parameters with complete integration with MES

- Multiple Poke Yoke through our whole process

- “State of the Art” vibration welders with 100 % parameters monitoring

- Leading edge technology with collaborative robots, AGV and vision systems

Our people.

Our engineering team has expertise in the full range of optic design roles from 3D modelling, simulation and output optimisation to high quality manufacturing system sourcing and product validation.

Contact us for more information.

Services

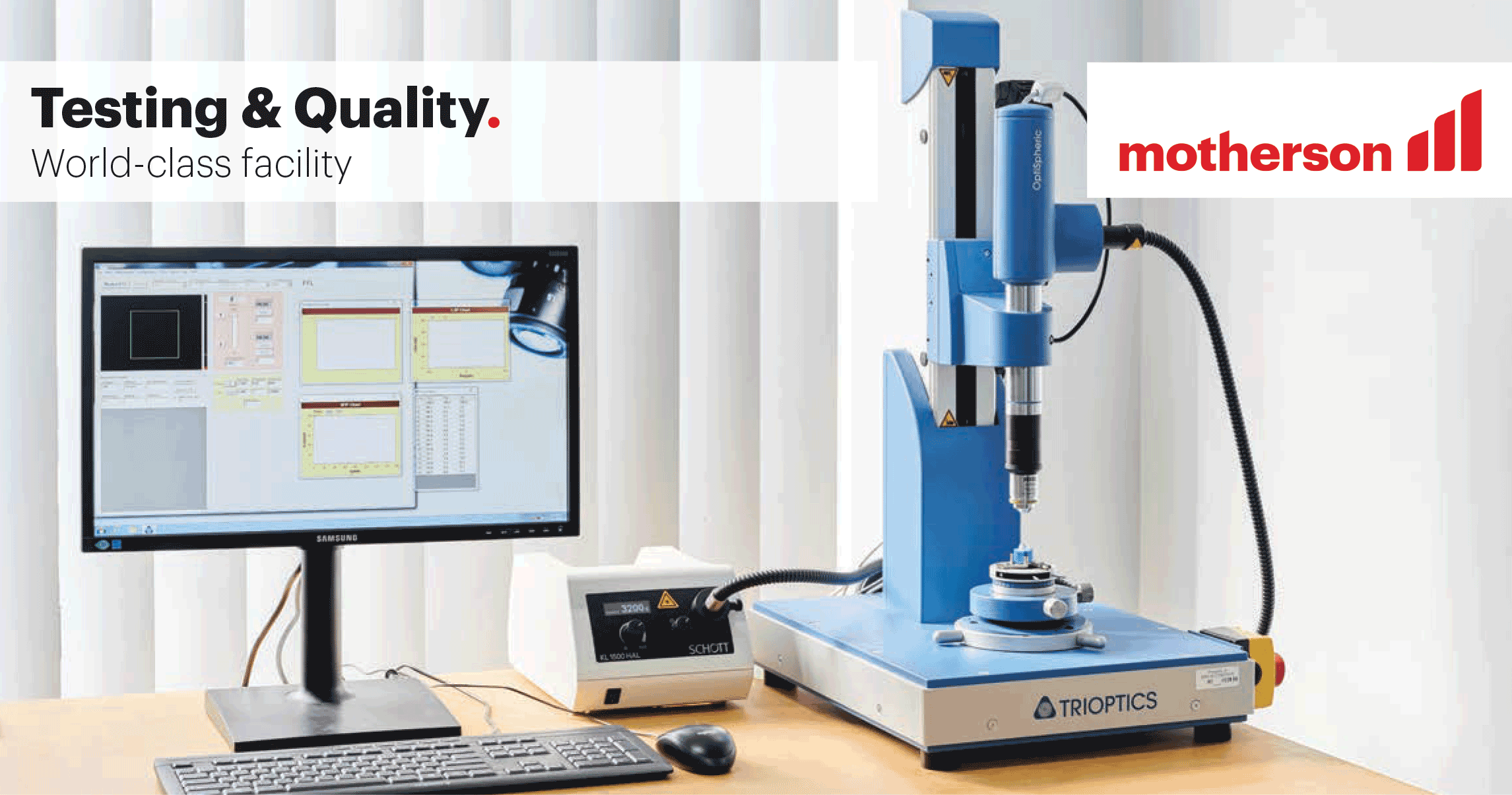

Testing & Quality

We are proud to provide our customers with complete product verification, validation and testing.

Your product is tested for durability and endurance at environmental extremes, performance and strength under vibration, tension and compression, as well as noise, light output and more.

The Motherson testing facility is certified to ISO 17025 and is NATA accredited for photometrics, while our manufacturing processes are quality certified to ISO 9001, ISO 13485 and IATF 16949. Our facility also meets environmental standard ISO 14001.

Overview.

We offer a broad scope of verification and metrology services for a wide range of applications including lighting, structures, electronic and mechatronic devices.

Quality is a core value; not only is it a priority for every product we create, but also every process we perform. It’s a prerequisite for our partnerships with customers, suppliers and R&D organisations, and just one of the reasons we place great importance on testing and metrology.

Our test facility is certified to IATF 16949 and has NATA accreditation to ISO 17025 for photometric testing.

Quality.

Our facility has the following quality certifications:

Environmental

- ISO 9001

- IATF 16949

- ISO 14001

- ISO 13485

- ISO 17025

Testing Capabilities.

Our comprehensive NATA-approved facility covers product performance measurement, noise level, light outputs and environmental exposure testing including:

Environmental

- Temperature and humidity

- (–40°C to +100°C) (to 95% RH)

- Salt spray

- Dust

- EMC – transient immunity/emissions and ESD protection

Durability

- Endurance of moving joints and manual mechanisms at environmental extremes

- Vibration endurance (sine, random or shock signal)

- Endurance of electrical switched devices at environmental extremes

- Impact durabilit

Performance

- Sound quality measurement

- Vibration, contact and non-contact, frequency response

- Kinematic metrology

- Electrical metrology

- Metrology of form

- Tension and compression strength of materials and structures

- Thermal imaging

- Photometric measurement and metrology

Our people.

Our qualified engineers, scientists and experienced testing staff have the required knowledge and skills to ensure test capabilities are delivered accurately and efficiently.

Contact us for more information.

Services

Elastomers

Motherson Elastomers is one of the largest rubber manufacturers and is the only manufacturer of the Silentbloc TM anti-vibration range in Australia. The Victorian based plant has full in house design capabilities, an extensive range of over 1900 material formulations and is an accredited ISO 9001 2015 & ISO 14001 2015 company.

View Complete Site